TURNKEY SOLUTIONS

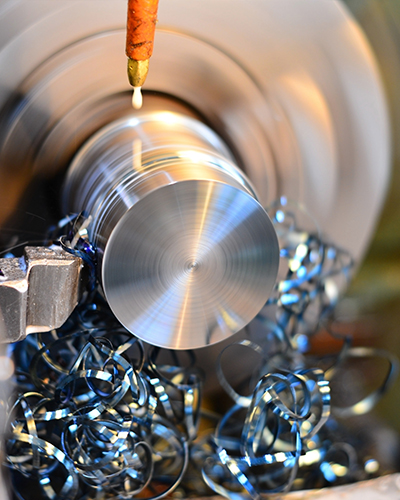

From mill to market, EAGS ensures value addition in every stage of our projects.With a specialism in end to end turnkey machining of downhole components and completion tools, Energy Alloys Global Solutions creates value for you and gives you the advantage. Staffed by a team of skilled machinists and engineers, our facilities produce precisely machined, finished and semi-finished parts while adhering to close tolerances.

These parts include quality down-hole components and completion tools such as mandrels, pup joints, stator tubes, rotors, PBR's, liner hangers, drill collars, crossover bodies, core barrels, and packers. EAGS specializes in managing the supply chain from concept to completion.

Thanks to our highly qualified multidisciplinary team and years of industry experience, Energy Alloys Global Solution has a command of all the activities that turnkey projects entail and a proven track record of successful projects.

Operational Excellence

Data-driven solutions enable collaboration, efficiency and full transparency.

Promise of Performance

High operating system standards ensure reliable end product.

Engineering expertise combined with effective material selection enables us to consistently meet and exceed industry standards and the challenges of the operating environment.

We offer the following services in each of the phases of our project:

Scope and Requirement

EAGS professionals assess all aspects of the project to create a bespoke solution. From feasibility, design, procurement, machining, inspection and delivery, you will have a clear vision of the project and confidence that it will be executed efficiently and on-time.

Supply Chain Synergies

EAGS has well established and long term relationships with our mill partners.

We are strategically located in the oilfield epicentres of the Western and Eastern Hemispheres, allowing seamless global coverage and providing us with an advantage in managing lead time differentials on behalf of our customers.

Machining Excellence

EAGS in-house machining capabilities are geared towards end to end turnkey machining of downhole components and completion tools including polished bore receptacles, pup joints, liner hangers and gauge carriers, flow couplings, cementing and staging tools. We have listened to our customers and continually invested in facilities and equipment to expand both our machining scope and capacity.